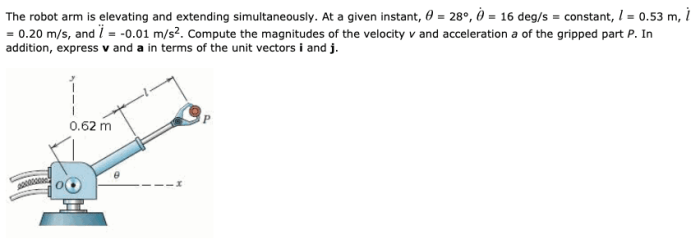

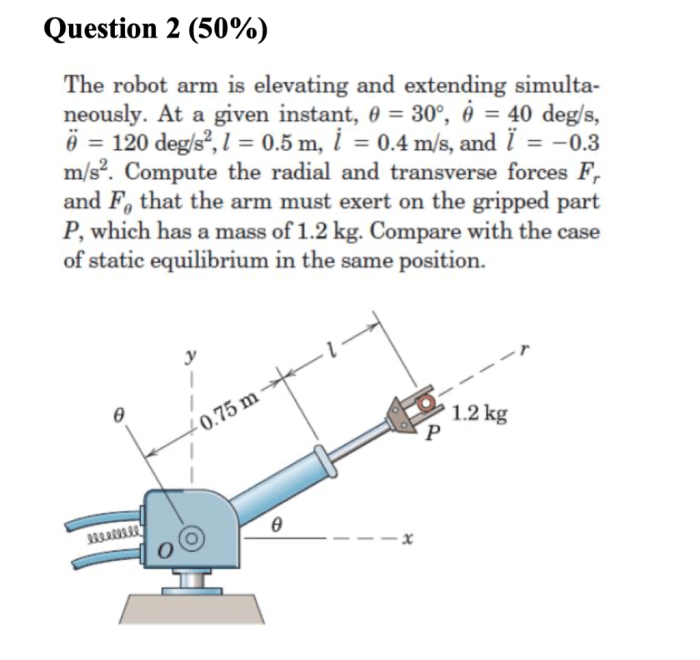

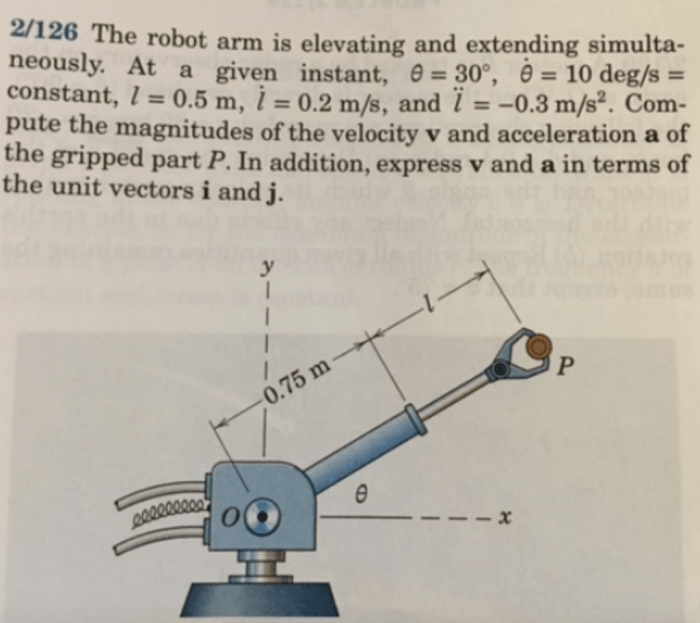

The robot arm is elevating and extending simultaneously – The robot arm’s simultaneous elevation and extension is a remarkable capability that significantly enhances its functionality and efficiency. This technology allows the robot arm to reach higher elevations while simultaneously extending its reach, enabling it to perform a wider range of tasks with greater precision and dexterity.

The elevation and extension mechanisms of robot arms are designed to provide optimal performance and control. Various methods are employed, each with its advantages and disadvantages. The control systems used to coordinate these movements are crucial for ensuring precise positioning and smooth operation, utilizing feedback mechanisms, sensors, and actuators.

Robot Arm Elevation and Extension Mechanisms

Robot arm elevation and extension mechanisms enable the robot to move its end-effector vertically and horizontally, respectively. These mechanisms are essential for a wide range of applications, including manufacturing, assembly, and logistics.

Linear Actuators

- Provide linear motion for both elevation and extension

- Compact and efficient

- Limited travel range and speed

Telescopic Actuators

- Extend and retract like a telescope

- Provide long travel ranges

- Can be bulky and heavy

Scissor Lifts

- Use a series of crossed links to achieve elevation

- Stable and reliable

- Limited extension capabilities

Control Systems for Elevation and Extension

Control systems ensure precise and smooth movement of the robot arm during elevation and extension. These systems use sensors to monitor the position and velocity of the arm, and adjust the actuation accordingly.

Feedback Mechanisms

- Provide real-time data on the arm’s position and velocity

- Enable accurate positioning and smooth transitions

- Examples include encoders, resolvers, and inertial measurement units (IMUs)

Actuators

- Convert electrical signals into mechanical motion

- Types include electric motors, hydraulic actuators, and pneumatic actuators

- Actuator selection depends on factors such as power, speed, and accuracy requirements

Applications of Simultaneous Elevation and Extension

Simultaneous elevation and extension enhance the functionality and efficiency of robot arms in various applications:

Manufacturing

- Loading and unloading parts from conveyors and machines

- Assembly of complex components

- Welding and cutting operations

Logistics

- Pallet handling and stacking

- Order picking and sorting

- Loading and unloading trucks

Design Considerations for Simultaneous Elevation and Extension

Designing robot arms capable of simultaneous elevation and extension presents challenges:

Weight Distribution, The robot arm is elevating and extending simultaneously

- Balanced weight distribution ensures stability and precision

- Counterweights or additional support structures may be required

Joint Flexibility

- Flexible joints allow for smooth and coordinated movement

- Consideration of joint stiffness, backlash, and lubrication

Power Consumption

- Simultaneous elevation and extension require significant power

- Energy-efficient actuators and power management strategies are crucial

Future Developments in Elevation and Extension Technology

Advancements in materials, sensors, and control algorithms will enhance the performance of elevation and extension mechanisms:

Lightweight Materials

- Reduce overall weight and improve energy efficiency

- Examples include carbon fiber composites and aluminum alloys

High-Precision Sensors

- Provide accurate and real-time feedback

- Enable precise positioning and smooth transitions

Advanced Control Algorithms

- Optimize movement trajectories and minimize energy consumption

- Adaptive control algorithms can handle varying loads and conditions

Commonly Asked Questions: The Robot Arm Is Elevating And Extending Simultaneously

What are the advantages of simultaneous elevation and extension in robot arms?

Simultaneous elevation and extension provide increased reach, enhanced precision, and improved efficiency for robot arms, enabling them to perform a wider range of tasks.

How do control systems ensure precise positioning and smooth operation in robot arms?

Control systems utilize feedback mechanisms, sensors, and actuators to monitor and adjust the robot arm’s movements, ensuring accurate positioning and smooth operation.

What industries benefit from the use of robot arms with simultaneous elevation and extension capabilities?

Industries such as manufacturing, healthcare, and logistics utilize robot arms with simultaneous elevation and extension capabilities to enhance productivity, accuracy, and efficiency.